SYLYSIA is Fuji Silysia Chemical’s micronized synthetic amorphous silica-gel product line. This material is highly versatile and can be used in many industries, including paints & coatings, plastics, inks and adhesives & sealants. SYLYSIA is an excellent agent for matting and anti-blocking polymer film. With variable pore volume, particle size and density, SYLYSIA can be widely applied into the paper and ink industries to improve receptivity and other functional coatings.

FEATURES

Porosity Control

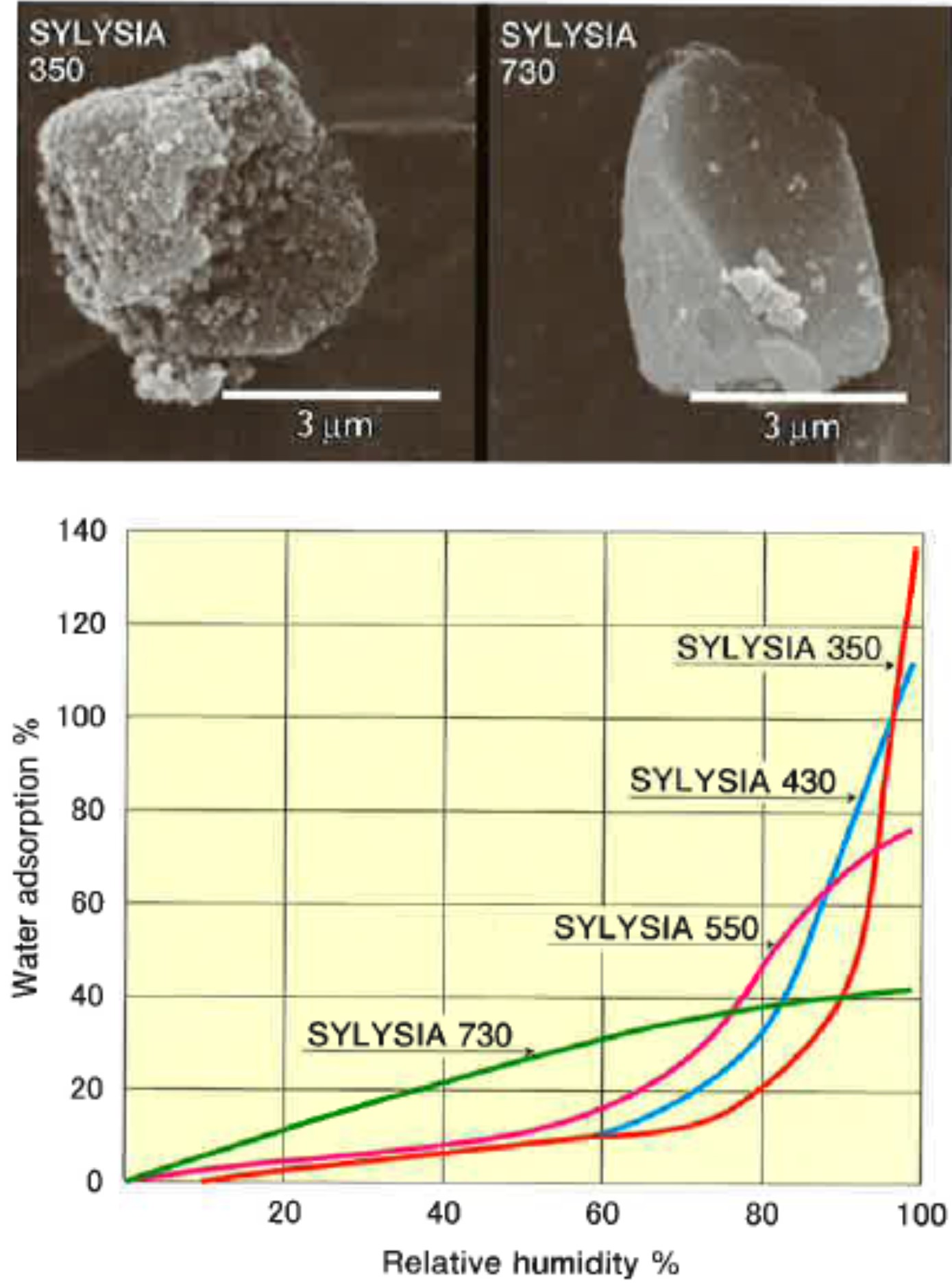

SYLYSIA has the variety of grades with controlled porosity. It makes possible to control from high density and small pore volume like SYLYSIA 700 series to low density and large pore volume like SYLYSIA 300 series. Besides, the adsorption isotherm also differs depending on the difference in pore diameter and pore volume. The SYLYSIA 700 series shows high moisture absorption rate at low humidity, while not high at high humidity condition. On the other hand, the SYLYSIA 300 series shows high moisture absorption rate at high humidity, exceeding to 1.4 times against its own weight. The other grades which have intermediate characteristics between the above can be available as well in the product line-up.

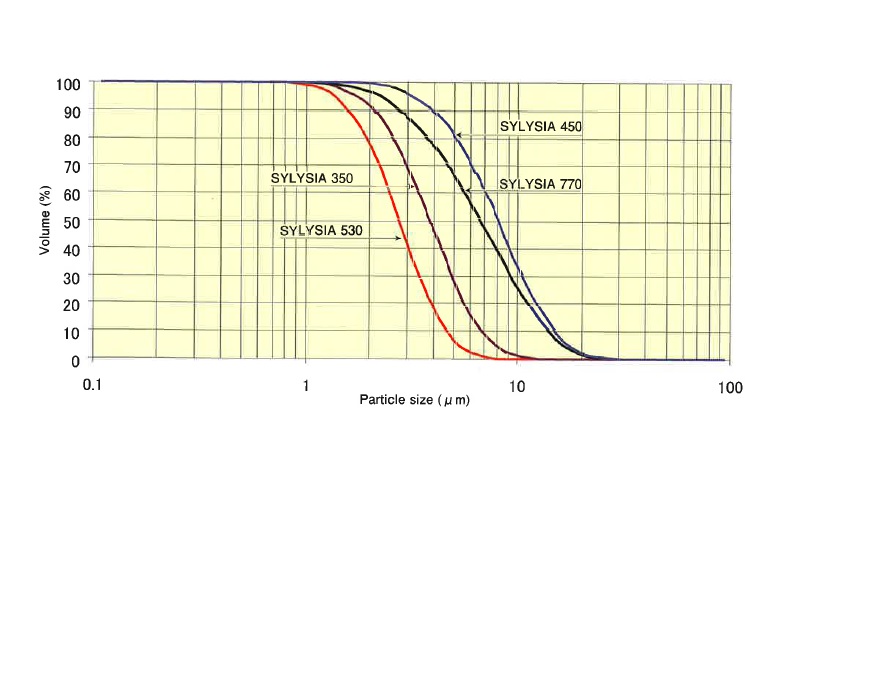

Controlled Particle Size

The particle size distribution is controlled under the range shown in the left figure. The smaller the particle size, the sharper the particle size distribution it shows. It is possible to control the particle size based on the corresponded application.

Surface Treatment

The silica surface is covered by the hydroxyl group (OH group) called “Silanol”. SYLYSIA treated with organic substances is available to improve the compatibility with solvents and resins. Furthermore, it is possible to improve the surface characteristics by corresponding its application.

PURPOSE

Industrial Applications

New Special Products

Fuji Silysia Chemical is constantly developing products with new applications and features. We have developed new special products.

・Anti-bocking agent for thin layer films

・High pore volume and high specific surface area

・Anti-scratch agent for coating

・Sedimentation stability for coating (anti-hard caking)

・Matting agent for UV paints

| Grade | APS(㎛)*1 | pH*2 | SA (㎡/g) | OA (mL/100g) | Treated | Characteristic / Application |

| SYLYSIA 300 | 1.7 | 7.5 | 300 | 330 | ー | Thin layer films |

| SYLYSIA 660 | 5.5 | 7.0 | 700 | 230 | ー | High pore volume

High specific surface area |

| SYLYSIA 852 | 5.0 | 5.0 | ー | 90 | ー | Anti-scratch |

| SYLYSIA 882 | 10.0 | 5.0 | ー | 80 | ー | Anti-scratch |

| SYLYSIA 328 | 2.9 | 7.5 | ー | 330 | 〇 | Anti-hard caking |

| SYLYSIA 358 | 3.9 | 7.5 | ー | 320 | 〇 | Anti-hard caking |

| SYLYSIA 448 | 6.2 | 7.5 | ー | 260 | 〇 | Anti-hard caking |

| SYLYSIA 446MU | 6.0 | 7.0 | ー | 210 | 〇 | Low viscosity / UV paints |

*1 : APS=Average Particle Size : Laser method *2 : 5% slurry

GRADE

| Grade | APS(μm) Laser method | pH (5% slurry) | Specific surface area (㎡/g) | Oil absorption (mL/100g) | Bulking value (mL/5g) | Net weight (kg) |

|---|---|---|---|---|---|---|

| SYLYSIA 250 | 5.7 | 3.0 | 280 | 330 | 60 | 10 |

| SYLYSIA 250N | 5.7 | 7.0 | 280 | 330 | 60 | 10 |

| SYLYSIA 310P | 2.7 | 7.5 | 300 | 330 | 110 | 8 |

| SYLYSIA 320 | 3.2 | 7.5 | 300 | 330 | 110 | 8 |

| SYLYSIA 350 | 3.9 | 7.5 | 300 | 320 | 90 | 10 |

| SYLYSIA 370 | 6.4 | 7.5 | 300 | 280 | 55 | 10 |

| SYLYSIA 380 | 9.0 | 7.5 | 300 | 280 | 37 | 15 |

| SYLYSIA 420 | 3.1 | 7.5 | 350 | 230 | 60 | 15 |

| SYLYSIA 430 | 4.1 | 7.5 | 350 | 230 | 55 | 15 |

| SYLYSIA 440 | 6.2 | 7.5 | 350 | 220 | 50 | 15 |

| SYLYSIA 450 | 8.0 | 7.5 | 350 | 220 | 47 | 15 |

| SYLYSIA 470 | 14.1 | 7.5 | 350 | 200 | 30 | 15 |

| SYLYSIA 530 | 2.7 | 7.0 | 500 | 170 | 35 | 15 |

| SYLYSIA 550 | 3.9 | 7.0 | 500 | 160 | 30 | 15 |

| SYLYSIA 710 | 2.8 | 4.0 | 700 | 100 | 20 | 15 |

| SYLYSIA 730 | 4.0 | 4.0 | 700 | 95 | 17 | 20 |

| SYLYSIA 740 | 5.0 | 4.0 | 700 | 95 | 15 | 20 |

| SYLYSIA 770 | 6.7 | 4.0 | 700 | 95 | 13 | 20 |

If you have any inquiries for more detail, please contact us by hitting the “Contact” button.