TECHNOLOGY & QUALITY

- HOME

- TECHNOLOGY & QUALITY

We are proud to be a specialized synthetic silica manufacturer with all our experience and knowledge.

Founded in 1965, we have strived by constant technical development to be a superior specialized synthetic silica manufacturer to a wide range of industries. As a result, we have achieved a very stable supply of high-quality silica with strict quality control and stable productivity through constant research and development.

From the beginning, we have continued to challenge research and technological development to provide a variety of products that meet the diverse needs of our customers.

Plants /

Facilities

We have the three manufacturing sites in Japan, located in Kasugai, Hyuga, and Ehime Additionally, and two sites overseas, one in the USA, and one in Italy.

We supply synthetic silica with world-class quality.

The know-how and technology we have built since our foundation, coupled with various global production facilities, ensure a stable supply.

Our plants and facilities can be viewed below.

Three Japanese and two overseas manufacturing sites

Our manufacturing sites in Japan specialize in the production of micronized silica products and silica for chromatography.

In the meantime, our plants overseas primarily offer micronized silica products.

We contribute to the development of local communities as well.

The production of a wide variety of silica products

We have facilities and R&D functions that enable a “ONE CUSTOMER ONE GRADE” policy in terms of our ability to produce exact silica properties that correspond with the needs of various industries.

Investing in the next generation of productivity and technological advancement, we specialize in producing synthetic silica with high-performance facilities and rationalizing the system.

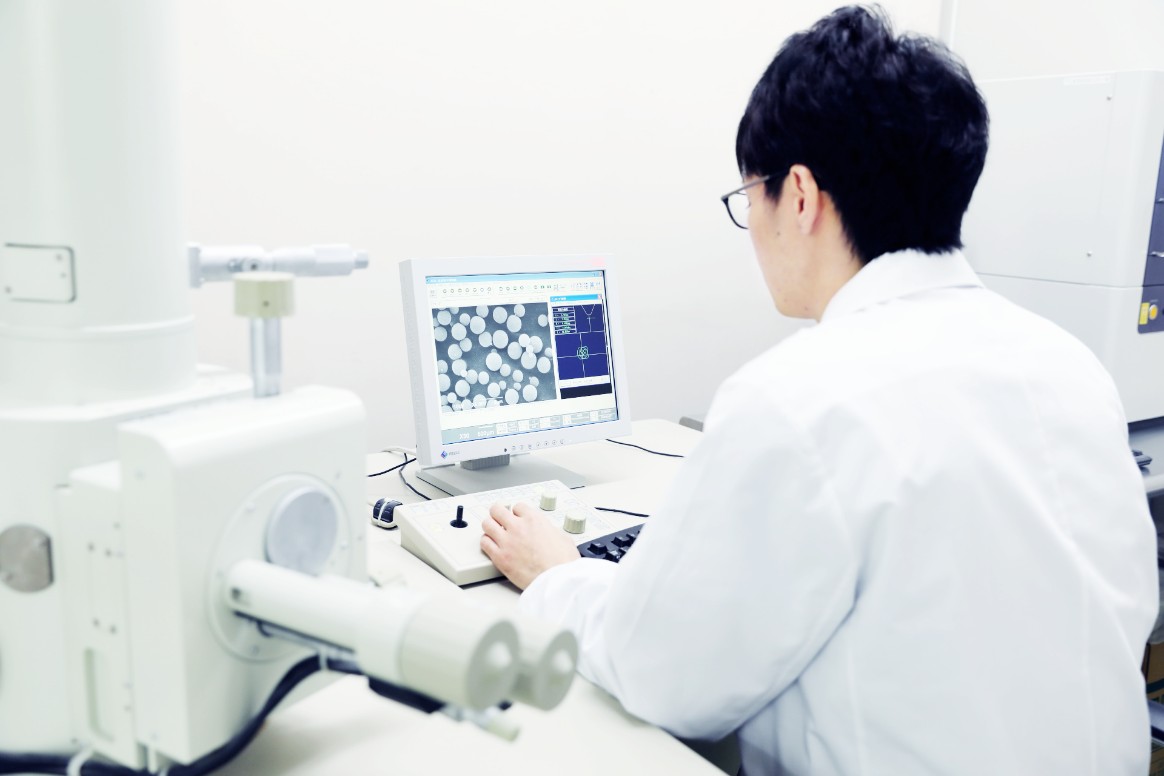

Technical skill

We are constantly pursuing silica research and development possibilities to supply products suitable for various commercial fields such as industry, pharmaceutical, food, housing, and culture.

We proudly introduce our unique technologies based on our proven performance as a manufacturer specializing in synthetic silica.

Our own technologyONE CUSTOMER ONE GRADE

We have built the sole technology of which we stand today. Our motto and philosophy ONE CUSTOMER ONE GRADE dictates our method of altering our particle size and other physical properties to precisely match the individual needs of our customers.

Technology for Particle Size Control

We have various options available in a wide range of product line-ups with the particle sizes from “mm” through “μm”.

Our own technology for particle size control can be applied to a specific individual type. We can offer products that are suitable to combine technologies a customer’s request.

Our R&D department is constantly developing new technologies and applying them to new products.

Technology for Pore Size Control

All silica gel products have complex pore structures. Our proprietor technology can control the pore structure. We have products with pore sizes ranging from a few to several hundred nm. By applying our technical knowledge of specialized pore size control, we can make it possible to correspond the needs from fundamental research to the mass production level.

These high-quality products are also applied in fields such as industry, chromatography and catalyst supports.

Technology for Surface Modification

The surface of silica gel is covered by groups (Si-OH). The silanol shows hydrophilicity which is one of the main characteristics of silica gel; however, there are cases that customers require different surface properties.

We can provide a variety of surface modifications at the customers’ request. This flexibility brings affinity for various applications, such as paints, plastics, chromatography, and catalyst supports.

Technology for Controlling Silica Shape

We have various shapes of silica gel, such as spherical, granular, and slurry.

It’s not only shape and appearance, but we also develop silica gels with various physical properties such as hardness and disintegration. In addition, we strive to create new types of silica gel to match requests from customers.

Quality Control

One of the reasons why our customers choose us is our stable supply and product quality.

We promise to provide extensive knowledge of synthetic silica and high-quality products through our strict quality management.

The expertise of our synthetic silica manufacturing makes strict quality control possible

To maintain our policy, “ONE CUSTOMER ONE GRADE, “we strive to manage high-quality without any compromise to our customers’ various needs.

We construct our quality management system to provide high-quality products that meet customers’ standards complying with ISO9001/14001.

Extensive knowledge and expertise in Testing and Analysis of synthetic silica

We have abundant knowledge and expertise in evaluation and analysis through long-term business relations with customers in various fields.

In addition, we are able to provide testing services for various standards such as Japanese Pharmacopoeia, additives for pharmaceuticals and foods, and raw materials for quasi-drugs.

registration/

certification

Food Additives Manufacturing License

Fertilizers / Feeds Licensed Manufacturing License

Pharmaceutical Products Manufacturing License

Certificated the Brewing Materials Standards Council

GMP Auditing Board for Pharmaceutical Excipients

HACCP, HALAL, Kosher Certification