The coatings industry is moving towards environmentally safe products with lower VOC requirements and uses of non-toxic pigments. SYLOMASK is an environmentally friendly anti-corrosive alternative to conventional lead, zinc and chromate pigments. SYLOMASK is a non-toxic anti-corrosive pigment based on ion-exchange technology using porous silica as a support.

FEATURES

Free of Heavy Metals

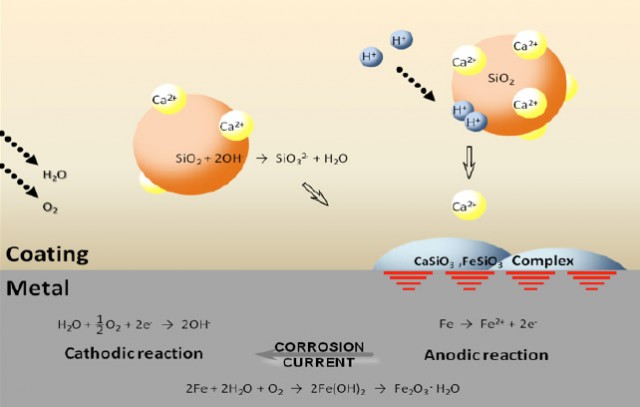

SYLOMASK is an environmentally friendly, anti-corrosive pigment that does not contain heavy metals. SYLOMASK is insoluble and remains in the film coating. The film coating structure is not destroyed due to the elution of rust preventives that occur with soluble anti-corrosive pigments. Therefore, the original performance of the film coating is maintained. The film coating structure is not destroyed because the elution of rust preventives does not occur as in the case with soluble anti-corrosive pigments. Thus, the original performance of the film coating can be maintained.

Low Specific Density

SYLOMASK has a less specific density than metal pigments comparatively so a smaller dosage of SYLOMASK can be used in coatings.

PURPOSE

Application

SYLOMASK exchanges aggressive ions, such as Na+ or H+, found in coatings for calcium or magnesium ions from the silica surface to deposit on the metal substrate, forming a protective layer. With a high ion exchange rate, SYLOMASK may improve shelf life without adding haze to the system while reducing weight via low specific gravity. It is best used for direct contact on a metal substrate.

- Non-toxic: This product is pigment composed of porous silica and calcium that does not contain any environmental pollutant.

- Long-lasting anti-corrosive effect: Base material of porous silica can achieve the anti-corrosive effect for long period due to the high ion exchange rate.

- Improvement of shelf life on coatings: Its insoluble particles do not cause voids and maintain stable coatings with long-lasting.

- Refractive index: The refractive index of it is 1.46 and closer to that of any resins. It facilitates transparency on coatings.

- Effect: The dosage by weight can be reduced compared with other anti-corrosive pigments.

SYLOMASK can be used in both solvents and water-based paints without problems.

GRADE

| Grade | APS(μm) Laser method | pH (5% slurry) | Oil adsorption (mL/100g) | Ion exchange |

|---|---|---|---|---|

| SYLOMASK 52 | 2.7 | 9.0 | 80 | Ca |

| SYLOMASK 55 | 3.6 | 9.0 | 60 | Ca |

| SYLOMASK 52M | 2.7 | 9.0 | 95 | Mg |

| SYLOMASK 22MR-H | 2.7 | 7.0 | 90 | Mg |