2021.11.16

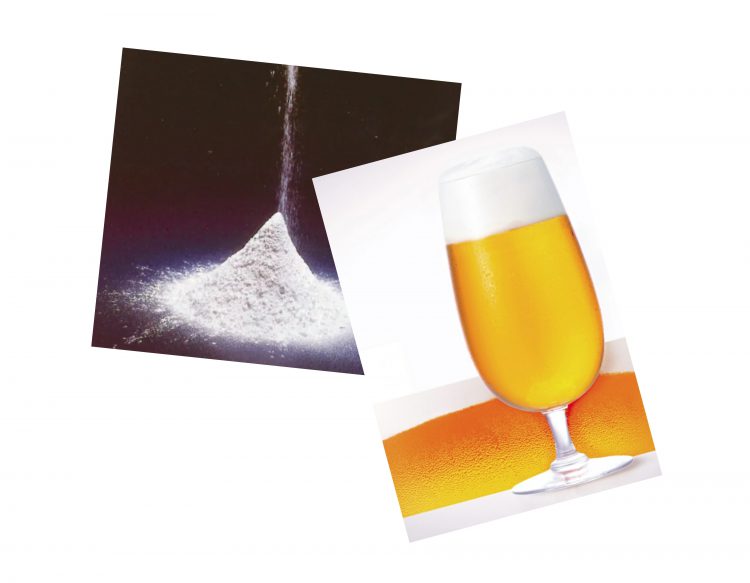

Development of Silica for Beer

The hue of a beer is its flavor

Nowadays, you can find a wide variety of shades and flavors of beer at a smart pub or other establishment. The pale hues of Pilsner and Weizen beers evoke images of a pleasant aroma and the feeling going down your throat, while darker hues, such as stout, evoke images of a rich, subdued flavor. In beer, appearance, such as color, transparency, and fineness of foam, greatly affects the image of taste. In fact, silica gel also helps to improve the image of such beer.

Clear beer

Beer that glistens beautifully like a sparkling jewel in the sunshine or under lighting. Brewers have long used a variety of methods to achieve their goal of creating such a beautiful beer. In recent years, various filtration methods and proteolytic enzymes have been used. ……… However, there was always the need to address various issues such as the balancing act with aroma and flavor, or the sacrifices made for the retention of foam. Is there a convenient material that can control turbidity without affecting flavor and foam?

Beer that glistens beautifully like a sparkling jewel in the sunshine or under lighting. Brewers have long used a variety of methods to achieve their goal of creating such a beautiful beer. In recent years, various filtration methods and proteolytic enzymes have been used. ……… However, there was always the need to address various issues such as the balancing act with aroma and flavor, or the sacrifices made for the retention of foam. Is there a convenient material that can control turbidity without affecting flavor and foam?

Considering prototype production of SYLOPUTE

About 40 years ago, Fuji Davison Chemical Ltd. (our company: current Fuji Silysia Chemical Ltd.) at that time was approaching a new field of “food additive as a filtration aid”. Around the same time, domestic beer companies were also looking for a filter aid suitable for beer production. The hopes for the future of both the beer company and the silica gel material manufacturer were pointing in exactly the same direction.

About 40 years ago, Fuji Davison Chemical Ltd. (our company: current Fuji Silysia Chemical Ltd.) at that time was approaching a new field of “food additive as a filtration aid”. Around the same time, domestic beer companies were also looking for a filter aid suitable for beer production. The hopes for the future of both the beer company and the silica gel material manufacturer were pointing in exactly the same direction.

There are various causes of turbidity in beer. The most typical cause is said to be a combination of proteins and polyphenols derived from the barley and hops used as ingredients. If either the protein or polyphenols are reduced, turbidity is less likely to occur. Proteolytic enzymes were commonly used in Japan at that time. By decomposing proteins, the cause of turbidity can be reduced. However, certain proteins were also involved in maintaining beer foam.

It was known that the proteins causing turbidity and those involved in foam retention differed in molecular weight. The most important feature of silica gel is its diverse pore structure, and we wondered if we could remove only the proteins that cause turbidity by controlling this pore structure.

This was the beginning of the study for the prototype of SYLOPUTE.

Development, Decision, Continuation and towards the future

Development started in the Research and Development departmentand the main factory at that time. Various sample prototypes were made with a focus on controlling particle and pore size, and product evaluations were also conducted at beer companies. The resulting products were two grades, SYLOPUTE 342 and 30.

Development started in the Research and Development departmentand the main factory at that time. Various sample prototypes were made with a focus on controlling particle and pore size, and product evaluations were also conducted at beer companies. The resulting products were two grades, SYLOPUTE 342 and 30.

The product was then improved with a focus on filtration and evolved into the best-selling SYLOPUTE 130.

The Hyuga Plant was the main supplier of products. The Hyuga Plant was planning a line to produce other products instead of SYLOPUTE. However, the decision by then President Takahashi to change the plan abruptly resulted in the Hyuga Plant’s production line configuration giving priority to SYLOPUTE. This decision enabled the Hyuga Plant to meet the large demand for SYLOPUTE later, and SYLOPUTE grew to become a core product of Fuji Silysia Chemical.

After that, the Hyuga Plant and the Technical Department, the backbone of the Research and Development Department, continued to improve the product to meet the changing market needs. Joint development with beer companies led to the high-performance grade SYLOPUTE 230, and then to the cross-flow compatible product SYLOPUTE 230CW. Product development continues at this moment,

The spirit of the company policy of

“ONE CUSTOMER ONE GRADE” is well.